We provide diverse machining solutions for the machinery, automotive, defense, and aerospace industries.

At Euro Metal, we combine advanced technologies with high quality to deliver the latest products to our customers.

Developments in the world and new technologies are closely followed and those that are applicable are brought into the company.

Euro Metal MachiningWe have been at your service since 2002

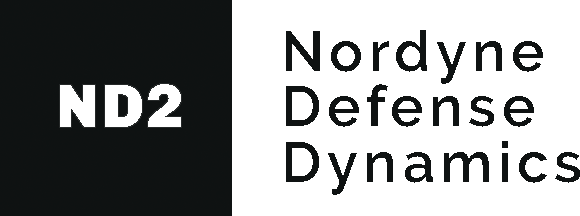

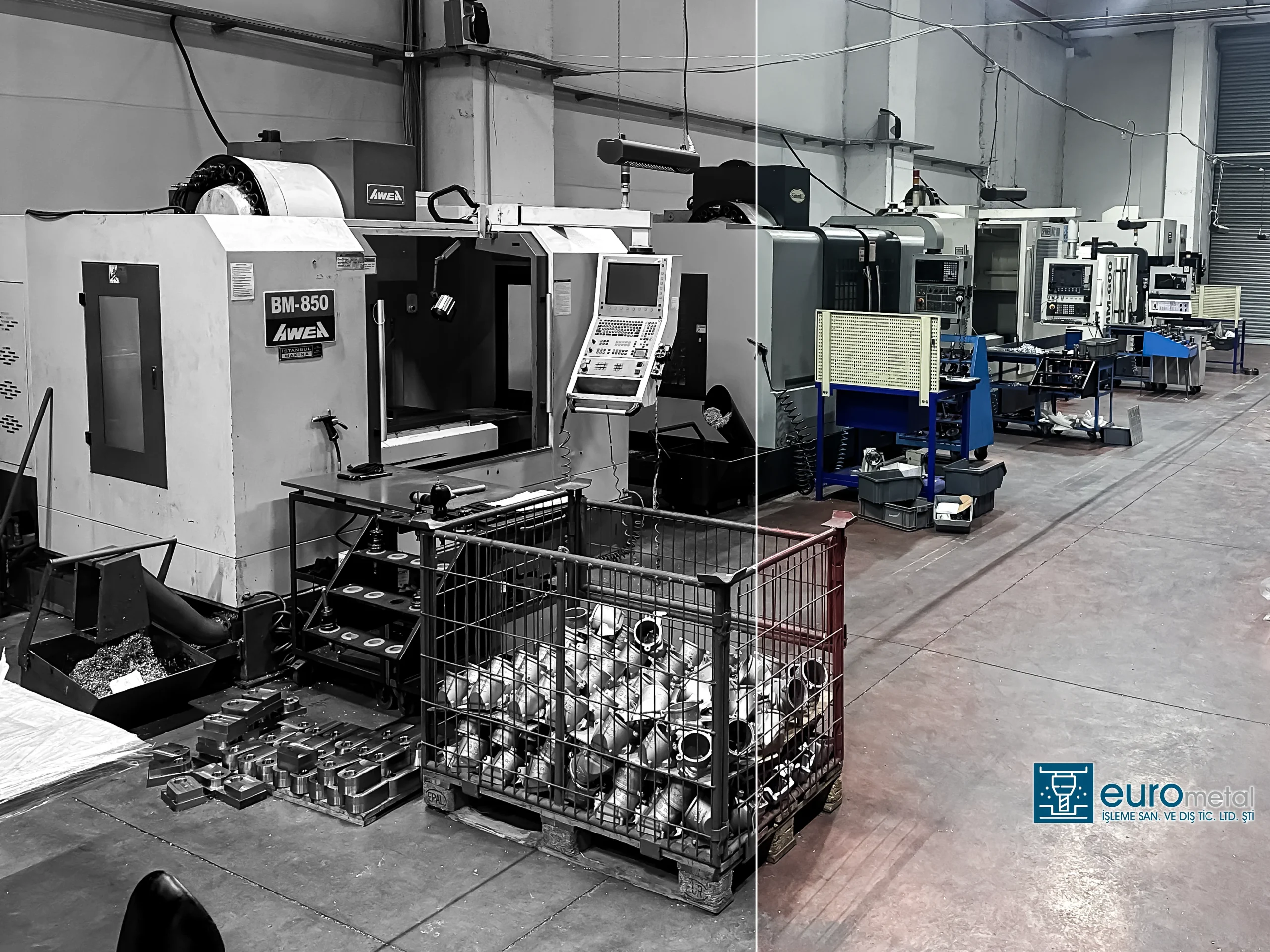

Founded in 2002, Euro Metal Machining began by producing vehicle spare parts with a focus on quality production. In 2005, we upgraded our machinery to CNC technology, quickly increasing our production capacity.

Driven by customer demands, we’ve expanded our customer base while consistently maintaining our commitment to quality.

Our Mission

At Euro Metal Machining, we place great importance on quality control and are committed to continuous improvement. We consistently enhance our production quality through regular staff training and by adopting the latest manufacturing technologies.

Since 2006, we have been a trusted supplier to leading companies in the automotive, machinery spare parts, packaging, and transportation sectors, particularly in Germany, the Netherlands, and the UK.

The most special products for the best customers

Euro MetalThe advantages of our company are in product quality.

We welcome your requests and suggestions. We are ready for productive and mutually beneficial cooperation.

While providing metal processing services, we perform special operations according to customers’ needs. We are waiting for you to meet needs such as production of products in special sizes, processes requiring precision and accuracy, and processing of special materials.

Euro Metal MachiningAll about metalworking

Metal processing is the work done to give the metal the desired shape using CNC machines and various benches. The most important and easy tool for metal processing is the CNC machine. The metal processing sector is a sector that develops day by day and is the backbone of the industry. The most important problem for the industry is to shape the metal and produce the required part. There is a solution to this problem with CNC machines and laser cutting devices. Metalworking machinery is used in various industries such as automotive, medical, marine, aerospace, plastics, molding, electronics and construction.

- Lathe Machines

- Milling machines

- Band Saw Machines

- Drills

- Circle Metal Cutting

- Metal Processing

- Machinery

- Sanding and Welding Machine

The main feature of metalworking machines is that workpieces are more suitable for shaping, as opposed to forming, depending on a wide range of metal properties such as hardness, temperature, durability and chemical resistance, the achievable and desired homogeneity of finished metal parts. Metalworking machines have many features. Although some of these properties are common to metals and plastics, they mostly differ when high hardness is considered.

Why choose EuroMetal?

It was truly a great experience to work with this company that specializes in CNC machining. They provided the precision and quality we needed for our project at the highest level. They also did their best to ensure our project was completed on time. I would definitely recommend it to others!

Working with this company for CNC machining exceeded my expectations. They completed our project perfectly with their extremely strong technological infrastructure and expert team. By consulting with us every step of the way, they ensured that our design achieved the best result. We were very pleased with their work.

We are very pleased to cooperate with this company for our CNC machining needs. They stayed in constant communication throughout the project process and quickly resolved any problems we encountered. Thanks to their quality workmanship and customer-oriented approach, our project turned out great. We definitely consider working again.

PartnersOur References